- Who We Are

- Programs

- B2B Programs

- B2E Academic Programs

TVSTS brings extensive experience and expertise in helping businesses across various domains adopt best manufacturing practices to streamline their operations effectively.

TVS-TS is committed to continuously enhancing our clients’ quality and performance through value-added solutions that drive improvements in Productivity, Quality, Cost, Delivery, Safety, and Morale (PQCDSM). Our holistic approach ensures sustainable business excellence.

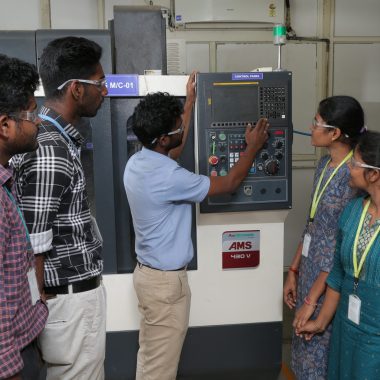

TVSTS specializes in identifying and analyzing the specific skills, knowledge, behaviors, and leadership qualities employees need to excel in their roles. Through comprehensive skill gap assessments, we pinpoint areas for improvement and address them with targeted, outcome-driven training and development programs.

Implement comprehensive policies, structured training, competency development, Total Employee Involvement (TEI), Kaizen practices, and process standardization to drive continuous improvement in quality, productivity, and operational efficiency.

Support businesses in achieving and sustaining certification across a range of ISO standards, including ISO 9001/IATF 16949 for Quality Management, ISO 14001 for Environmental Management, ISO 13485 for Medical Devices, and ISO 45001 for Occupational Health and Safety. Our expert guidance ensures compliance, continuous improvement, and long-term operational excellence.

Implement the 5S methodology to create an organized, efficient, and safe workplace that boosts productivity and minimizes waste.

Adopt comprehensive maintenance strategies to maximize equipment efficiency and minimize downtime, driving higher productivity and operational reliability.

Utilize lean manufacturing principles to eliminate waste, optimize processes, and maximize productivity, leading to cost savings and enhanced quality.

Enhance communication and operational efficiency using visual management tools that simplify performance monitoring and help quickly identify areas for improvement.

Synchronize production schedules to ensure materials are available exactly when needed, reducing inventory costs and improving cash flow.

Develop and implement strategies to enhance overall productivity.

Drive continuous quality improvement initiatives to elevate product and service standards, ensuring customer satisfaction and loyalty.

Employ systematic approaches to identify and resolve issues, fostering a culture of continuous improvement and operational excellence

Apply statistical methods to improve quality and reduce defects, resulting in higher customer satisfaction and lower operational costs

Analyze and optimize the flow of materials and information to identify bottlenecks and enhance process efficiency, ensuring smooth operations.

Apply visual scheduling systems to manage workflow effectively, reducing lead times and inventory levels while improving process control.

Reduce setup times to increase production flexibility and efficiency, enabling quicker responses to market demands.

Implement mistake-proofing techniques to prevent errors and ensure quality, reducing the costs associated with rework and defects.

Copyright © 2025. All rights reserved.