- Who We Are

- Programs

- B2B Programs

- B2E Academic Programs

Training Centres

We have 4 training centres, 3 in Tamil Nadu and one in Andhra Pradesh. Each centre has a capacity of 20,000+ square feet of training space. We have over 20 labs, 4 automotive workshops and 20 classrooms.

Capacity

Each centre has the capability to train up to 500 personnel per day.

The metrology lab is equipped with precision instruments and gauges for measuring linear and angular dimensions, as well as surface texture.

The program focuses on:

The CNC lab is equipped with precision CNC Horizontal Turning centres (HTC) and Vertical Machining centres (VMC). This lab provides trainees with the opportunity to learn CNC machine operations and gain practical experience in programming, simulation, and machining processes.

Lab activities include:

The Fitting & Conventional Machine-shop is furnished with workbenches, vices, hand tools and conventional machines such as Lathe, Drilling and Milling machines.

The workshop practices include:

The Welding Lab is an authorized training centre by the Indian Institute of Welding and a training partner of Tamil Nadu Skill Development Corporation. It is equipped with an Arc Welding Machine, MIG/MAG Welding Machine, TIG Welding Machine, Brazing, Gas Welding, and a Cutting Unit.

The Lab activities include:

The Maintenance shop is furnished with Gear, Belt & Chain drive units, Centrifugal pumps, Lubrication kit, Bearing mounting demo kits, Hand tools, Fasteners demo kits.

The workshop practices include:

The Automobile Shop features working models and cutaway sections of key components, along with fully equipped workstations and tools for the dismantling and assembly of engines and 2/3-wheeler vehicles. This setup enables hands-on training and provides a comprehensive learning experience for understanding vehicle mechanics and systems.

The workshop practices include:

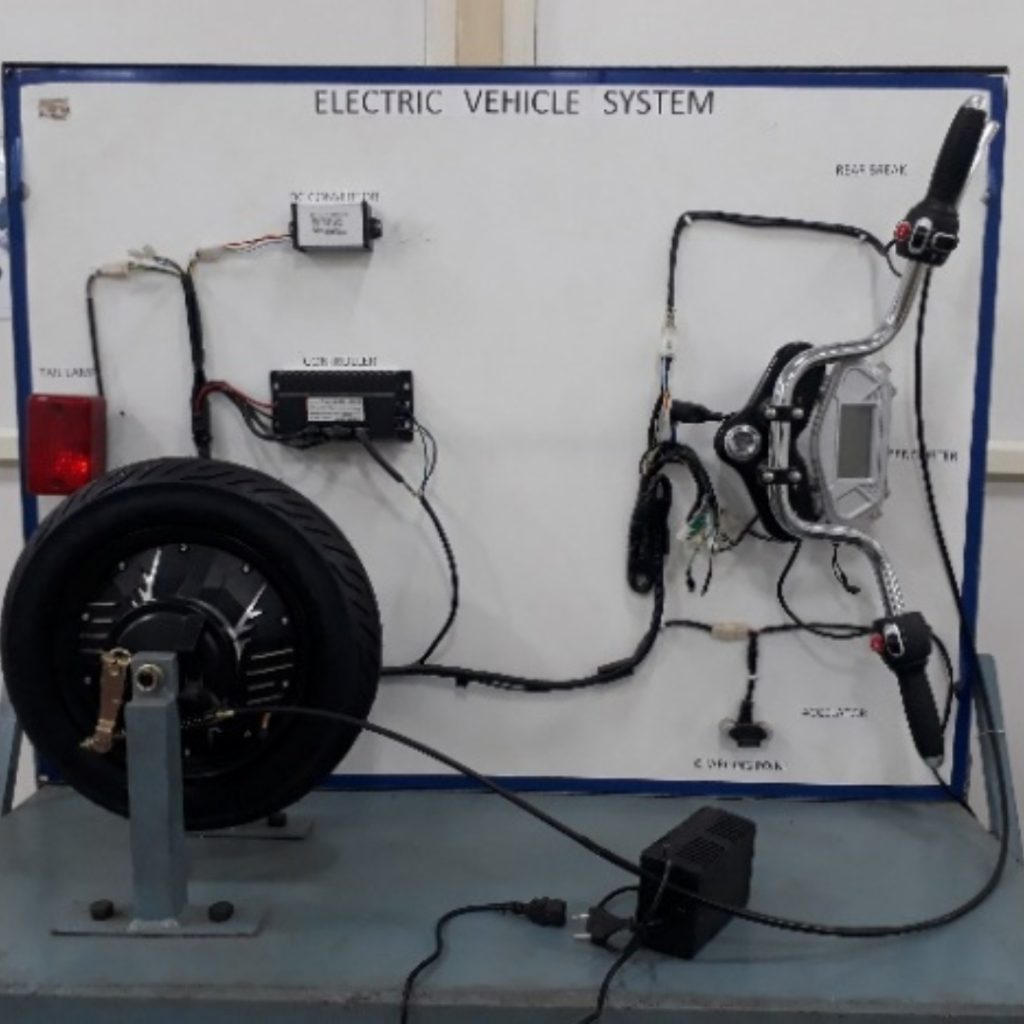

The Electric Vehicle (EV) Lab is fully equipped with a range of EV components, test benches, battery management systems, and simulators, providing trainees with hands-on experience in handling, maintaining, testing, and troubleshooting electric vehicles. This state-of-the-art facility is designed to help trainees develop specialized skills and become proficient in EV technology, ensuring they are well-prepared to work with the latest advancements in electric mobility.

The Lab activities include:

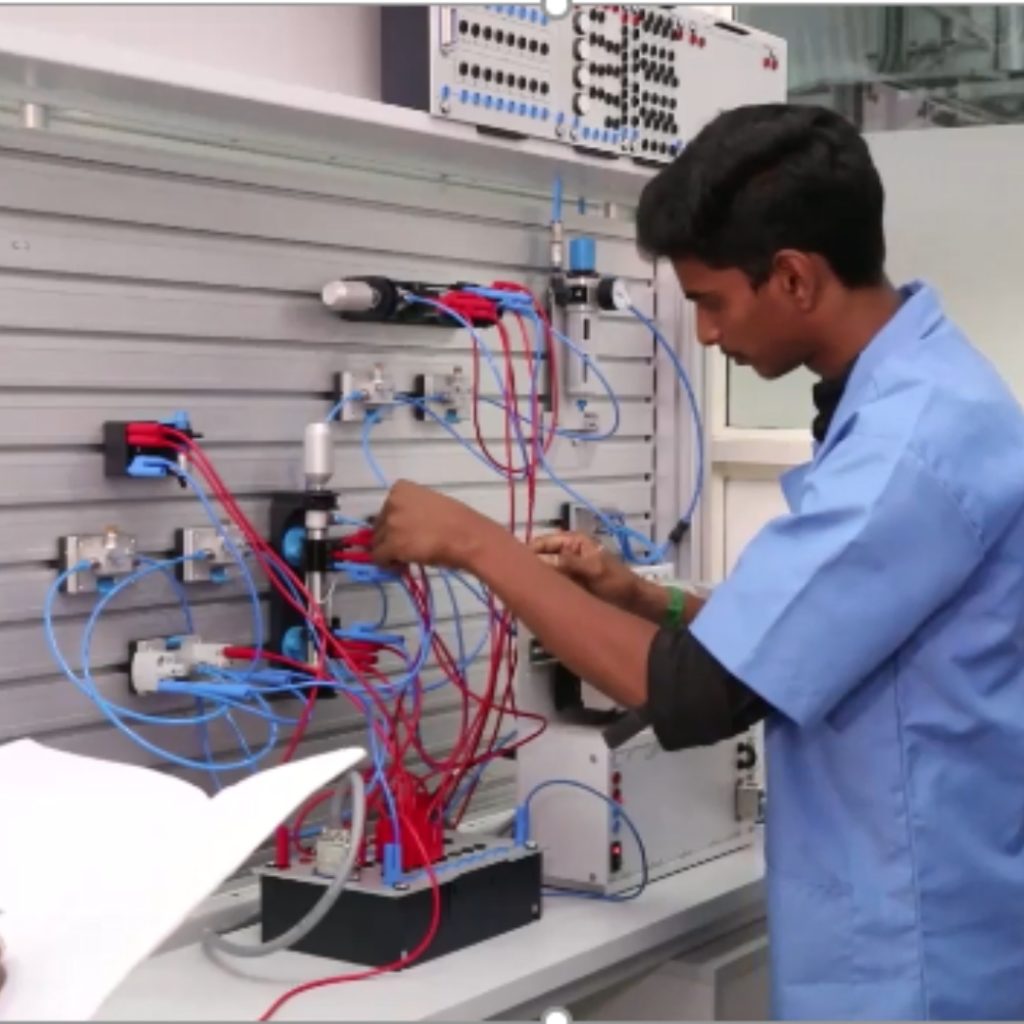

The Pneumatics Lab is equipped with Festo pneumatic systems, including components such as valves, actuators, and sensors. This facility allows trainees to perform experiments and gain hands-on experience in designing, testing, and troubleshooting pneumatic systems commonly used in various industries.

The Lab activities include :

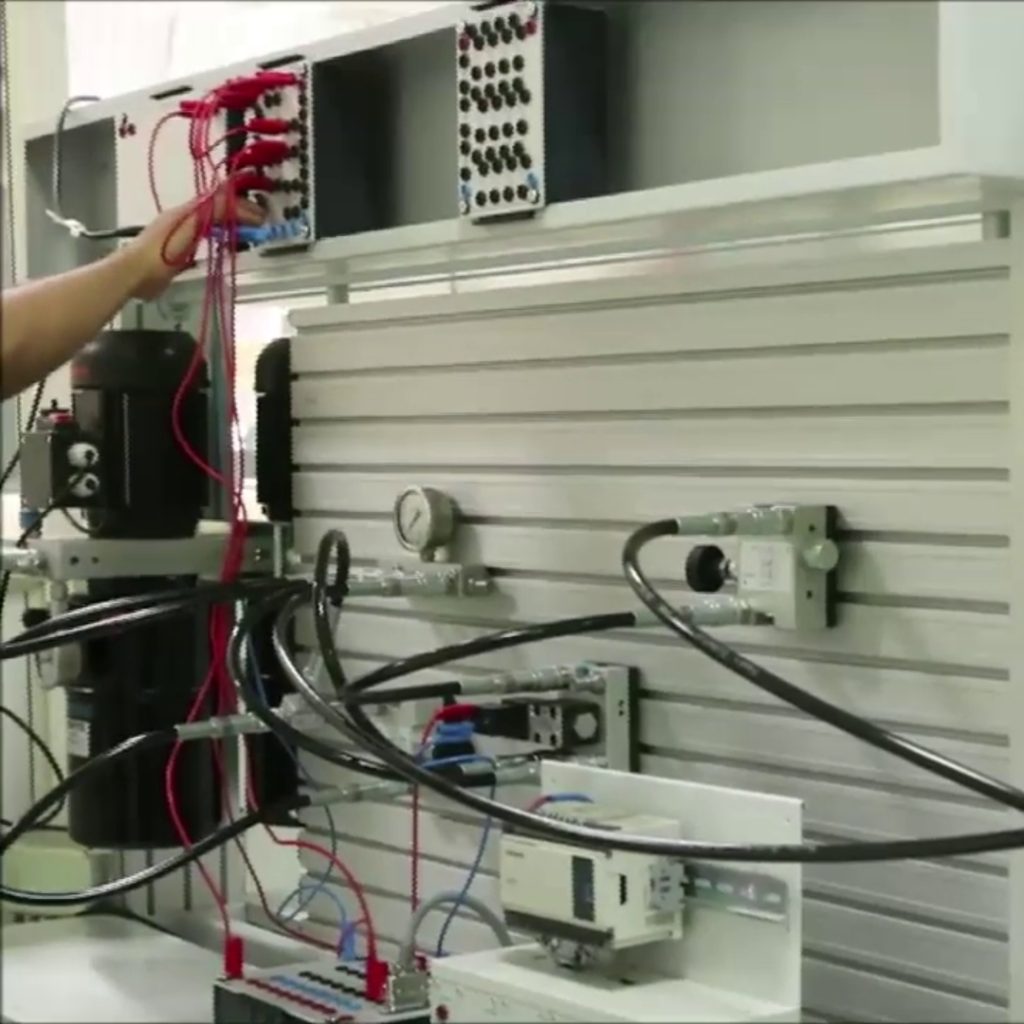

The Hydraulics Lab is equipped with Festo systems, including components such as valves, cylinders, and sensors. The lab enables trainees to conduct experiments, explore fluid behavior, and gain practical experience in designing, testing, and troubleshooting hydraulic systems used in various industries.

The Lab activities include :

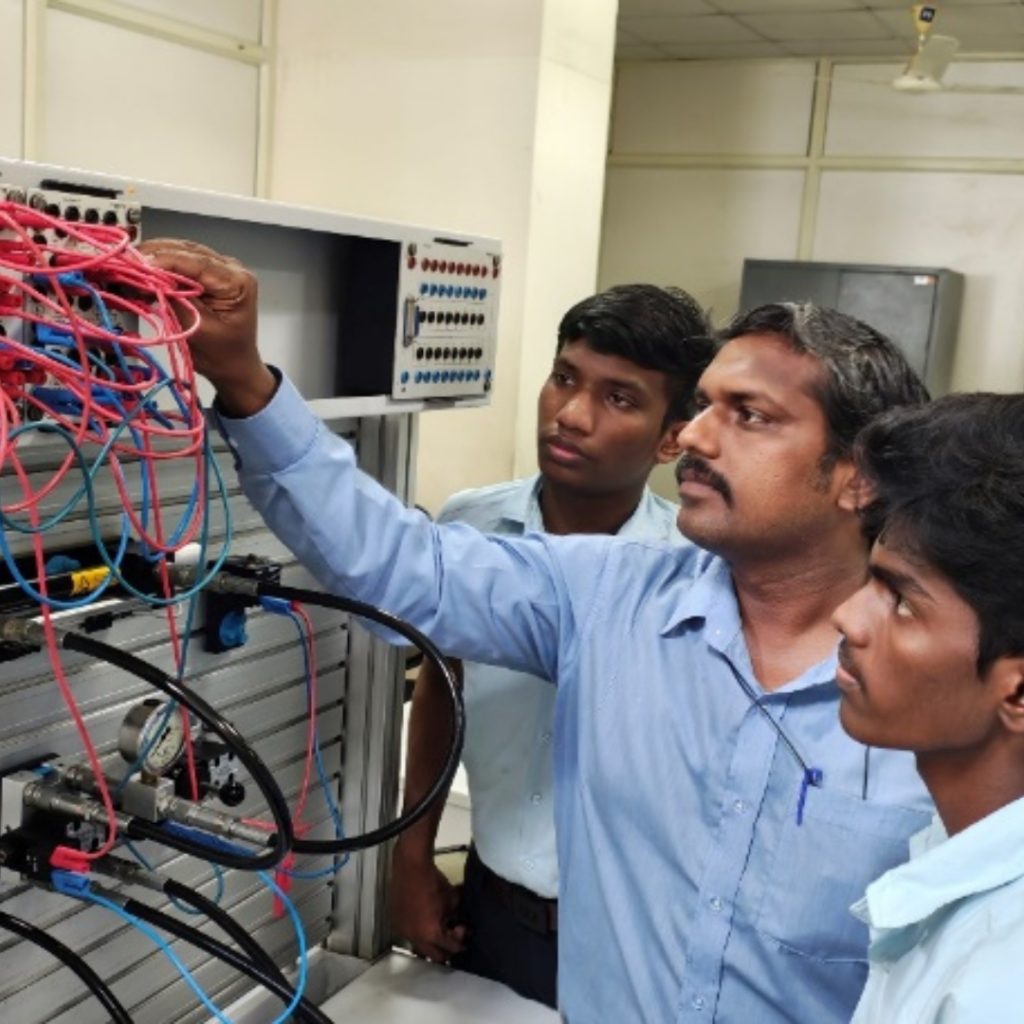

The PLC (Programmable Logic Controller) Lab is designed to provide practical training in industrial automation and control systems. Equipped with PLC kits , HMI, actuators, and control panels, the lab allows trainees to design, program, and troubleshoot PLC systems. It offers hands-on experience in programming logic, system integration, and real-time control applications, preparing trainees for careers in automation across various industries.

The Lab practicals include:

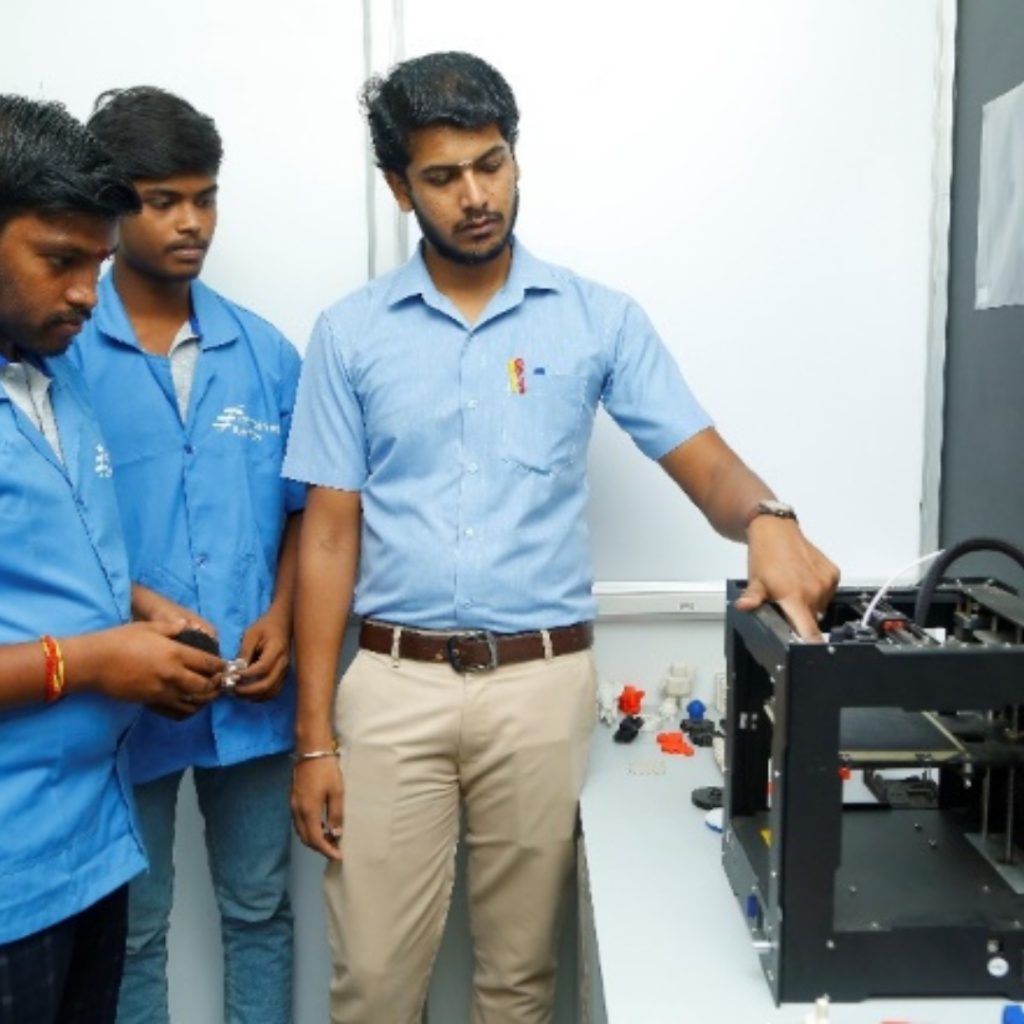

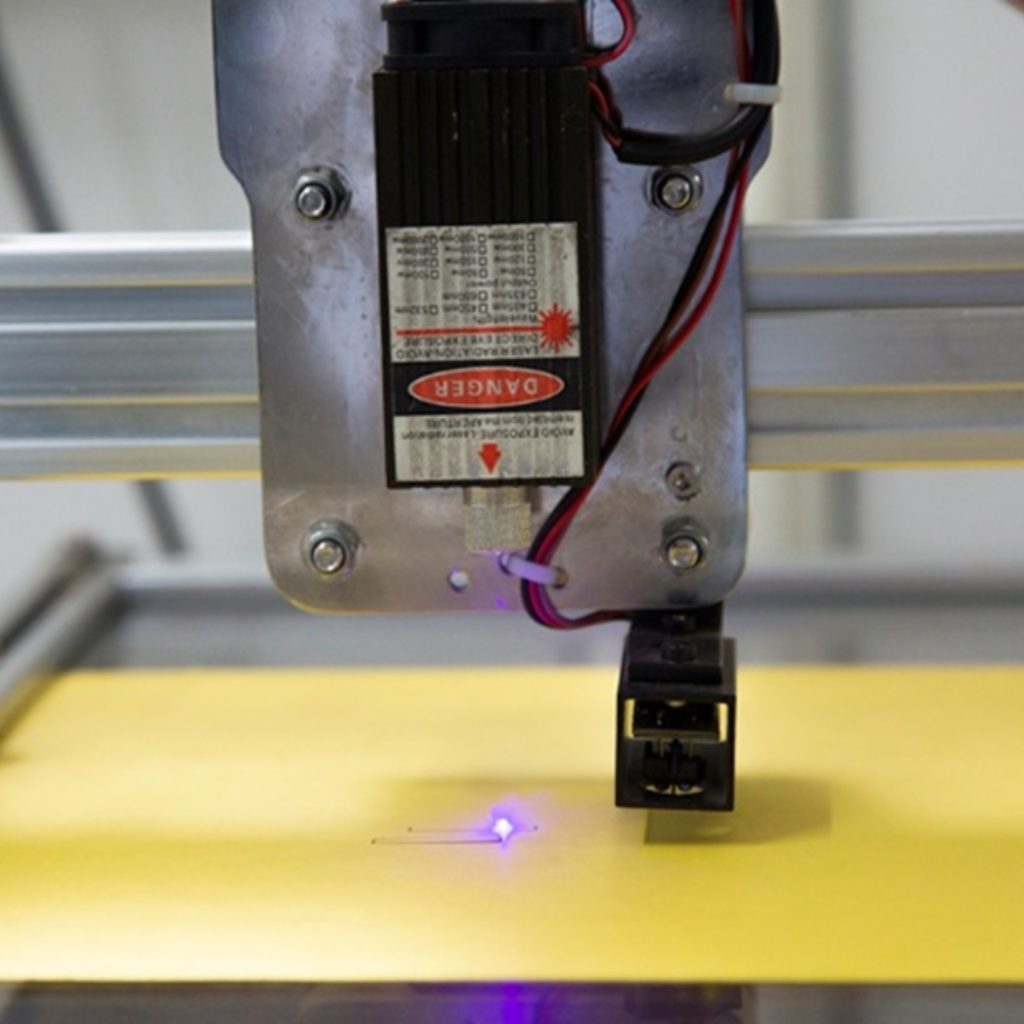

The Additive Manufacturing Lab is equipped with advanced 3D printing technologies, enabling the creation of prototype parts through layer-by-layer deposition by FDM. Trainees can design, model, and produce custom components, gaining valuable skills in rapid prototyping, product development, and additive manufacturing techniques used in various industries.

The Lab activities include:

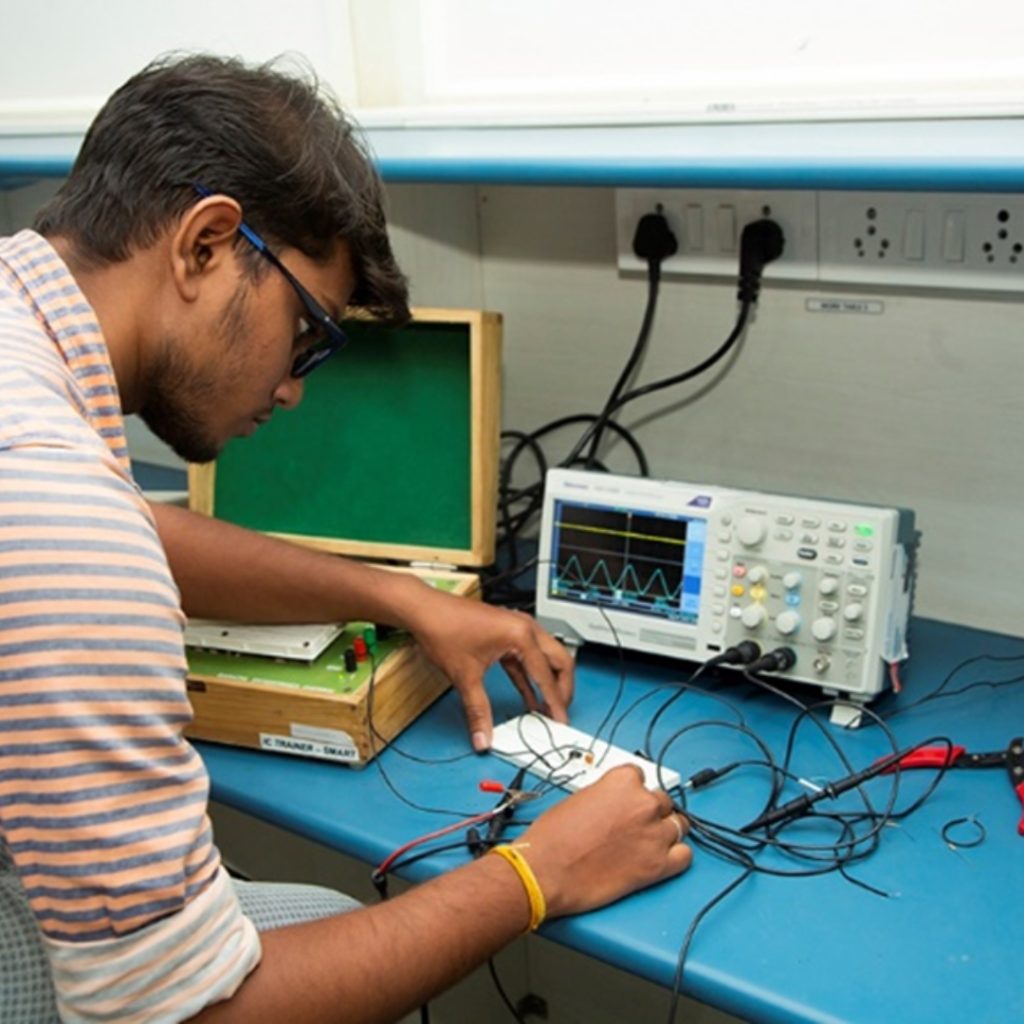

The application lab is equipped with various industrial applications in different microcontrollers (PIC, TI, Renesas), providing hands-on training in designing and programming embedded systems

The lab activities include:

The soldering lab is equipped with temperature-controlled soldering stations for soldering, desoldering, testing, troubleshooting, and component placement.

The Lab activities include :

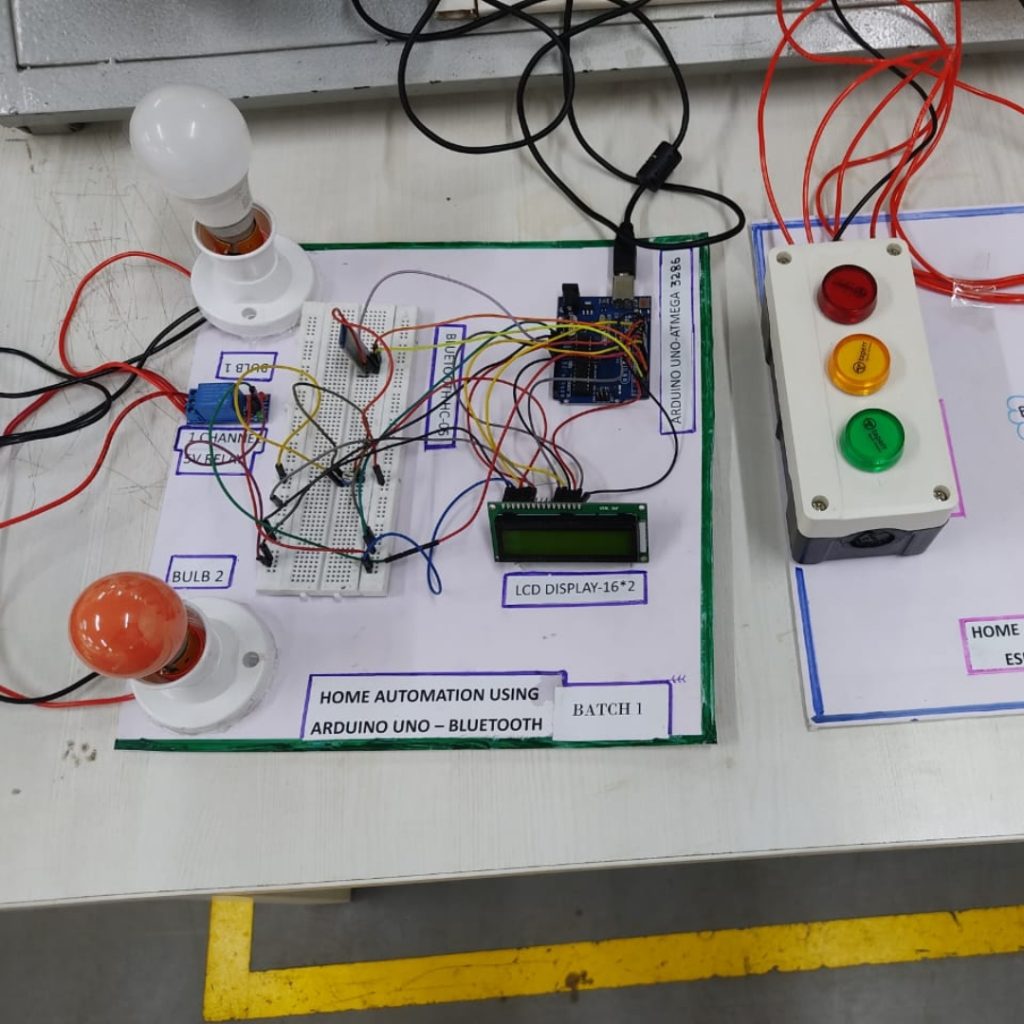

The Firmware & IoT lab is equipped with various microcontrollers and IoT controllers, allowing users to develop code using IDEs ( MP Lab , Arduino IDE , STM32 cube , MSP430 etc..)

The lab activities include:

Copyright © 2025. All rights reserved.